What is “OPC”?

OPC (OLE for Process Control) is an industry standard created with the collaboration of a number a leading worldwide automation and hardware software suppliers working in cooperation with Microsoft. The organization that manages this standard is the OPC Foundation www.opcfoundation.org . The Foundation has over 150 members from around the world, including nearly all of the world’s major providers of control systems, instrumentation, and process control systems, including Hertzler Systems.

Why is OPC important?

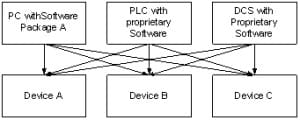

The use of microprocessors has proliferated in manufacturing plants, and they often do not work together. A key reason for this problem is that interfaces are not standard. In the absence of any standard, vendors have developed proprietary hardware and software solutions. The cost of integrating the different systems and the long-term maintenance and support of an integrated environment can be significant.

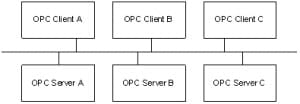

The solution is having a standard that provides real plug-and-play software technology for process control and factory automation where every system, every device and every driver can freely connect and communicate. Having such a standard makes possible the prospect of totally seamless, truly open and easy enterprise-wide communications between systems and devices, from plant floor to MIS (Management Information System) and beyond.

OPC will bring the same benefits to industrial hardware and software that standard printer drivers brought to word-processing.

This:

Becomes:

What are the key components of an OPC system?

OPC creates an interface between hardware and software systems. The key hardware components of this are some type of device that we want to read or write data to (typically a PLC – Programmable Logic Controller), a person computer, and some type of communication protocol (Ethernet is common). The key software components are an OPC Server (such as RSLinx, KepServer) which reads and writes data to the device, and an OPC Client (such as GainSeeker SPC, or a SCADA package such as Intellution or Wonderware). Hertzler’s GainSeeker Suite can act as both an OPC Server and and OPC Client.

What are the costs associated with setting up an OPC system?

The costs are dependent on the type of PLCs used, the communications protocol used and the number of clients. Each system is different and the costs can vary greatly. A typical starter system might run between $5 – $10,000. Without OPC connectivity, an interface between devices and software might run into hundreds of thousands of dollars.