GainSeeker Platform Library Enhanced OEE Kit Released [Instant Download]

This week we released our newest edition of the GainSeeker Platform Library – an enhanced OEE Kit.

Overall Equipment Effectiveness (OEE) is a powerful tool for evaluating manufacturing performance.

The enhanced OEE Kit assembles knowledge and wisdom for deploying OEE in manufacturing. Moreover, it provides guidance for maximizing the value of OEE across the supply chain.

There are many well-established OEE offerings already available in the marketplace. What does Hertzler bring to the table?

Other options

Current offerings fall into two main camps:

- Point solutions

- Subsets of massive enterprise solutions

Both of these have advantages and disadvantages. Let’s look at each of these.

Point solutions sub-optimize OEE data

Point solutions are the cotton candy of the OEE solutions: they look good on a stick and the initial taste is kind of a rush, but it doesn’t provide sustenance for the long haul. OEE point solutions are quick to set up and use, and they do a fine job of displaying current performance at a machine or production line. Making this information visible is an admirable step forward, but if you stop there you risk sub-optimizing the value contained in your OEE data.

Point solutions tend to treat OEE data as a no value throwaway. The data rolls off and is discarded after the local device is filled. Sometimes these systems provide means to log data to a database, but any further analysis requires custom software.

Finally, many OEE point solutions make it very difficult to aggregate data from multiple production lines, or across a supply chain. The data is often locked up in a device and inaccessible from other equipment or locations.

Subsets of massive enterprise systems are cumbersome to deploy and use

At the other extreme, there are a number of massive enterprise systems that offer OEE modules. These modules do not stand alone, and the implementation (not to mention cost) effort is substantial.

Our vision for an optimized OEE solution

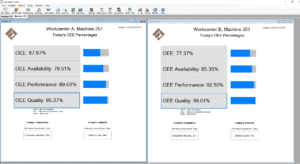

The first requirement of any OEE solution is that it is easy to set up. It should interface readily with a wide variety of production equipment using standard protocols (such as OPC or MTConnect). It should also support human interfaces so you can tap into the knowledge of the people closest to the point of production when needed (to log downtime reasons, for example). It should provide real-time visibility into manufacturing performance at the point where the data is generated.

Second, an optimized OEE solution should roll data from all assets from all plants into a central location. This data should be tagged with the source of the data (Plant, Machine, Line, Asset, and so forth), and the data should be retained so it can be mined for useful intelligence.

Finally, the ideal OEE solution should make it easy to explore historical production data using descriptive and predictive analytics. The right tools make it easy to pinpoint or even anticipate problems.

Several years ago we recognized an important gap in the market and built OEE functionality into GainSeeker Suite for Statistical Process Control. Now we’ve compiled our experience into a new downloadable kit for the GainSeeker Platform Library.

The new GainSeeker Platform Library OEE Kit

The new OEE Kit builds on our comprehensive overview of OEE, and includes:

- An overview of the OEE Kit

- Guidelines for designing an OEE system for your company

- Tips for getting started in deploying OEE in manufacturing

- Sample installable data sets that include:

- Recommended data structures

- Sample data collection scripts

- Sample dashboards and desktops

- Videos introducing the OEE Kit

Click here to download the enhanced GainSeeker Platform Library OEE Kit.