What happens when a market-leading electronics manufacturer has a field failure? As you can imagine, it’s a big deal because it directly affects the manufacturer’s relationship with their customers. Too many bad experiences and you drive your customers away.

What happens when a market-leading electronics manufacturer has a field failure? As you can imagine, it’s a big deal because it directly affects the manufacturer’s relationship with their customers. Too many bad experiences and you drive your customers away.

Thanks to social media, every manufacturer is plugged directly into the world community.

The musician who made a major airline play a different tune

My favorite story is about the use of social media to hold a company accountable for the quality systems issues is the 2009 David and Goliath encounter between musician Dave Carroll and United Airlines. Carroll, a musician from Halifax who was enroute to a gig in Ohama, saw his guitar thrown by baggage handlers.

After dealing for months with unsupportive customer service reps, Carroll turned on his creative juices and produced a series of razor-sharp, humorous music videos, a book, and a whole new career. The videos are widely credited with causing a 10 percent, $180 million drop in United’s stock.

The immediacy of social media is exacerbated by an increased reliance on contract manufacturers, and the consolidation of small footprint manufacturers into larger holding companies and brand owners. This creates longer supply chains, and brand owners are likely to have much less direct control over the final product.

A recent report by Gartner (“Supply Chain Is Missing the Mark on Quality”, 18 February 2015 by Simon F Jacobson, Janet Suleski, Ray Barger Jr, Ken Chadwick. Andrew Stevens, and Michael Dornan) notes that although quality receives strong endorsement and support from executive sponsors:

“Only 22% of the respondents in a 2015 Gartner study on quality in the supply chain claim quality as an integrated function of their supply chains, and even fewer report it as a discipline. It’s no wonder that over half of the high-profile quality failures of the past decade, ranging from flawed product launches, customer and patient safety incidents, and product recalls, are rooted in the extended value chain.”

Integrating quality thoughout the supply chain

So how do you go about integrating quality across your supply chain?

Our electronics manufacturer can provide some guidance.

As I said, a field failure is a big deal because it undermines the customer’s confidence and trust.

Already known as a market leader for technology and innovation, this manufacturer had to demonstrate they could continue to drive innovation (and thus retain their market leadership position). At the same time, they had to ensure a great customer experience, and deliver a defect-free product. The push for technical innovation could outstrip the supply chain’s capacity to deliver.

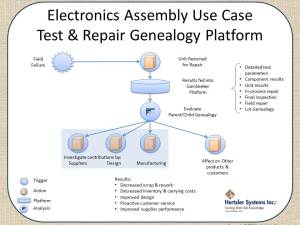

This manufacturer already had a system for repairing failed units and returning them to service. However they did not have a system for effectively managing the wealth of data they were already capturing about that repair, and other indicators up and down the supply chain. Data ended up in a handful of disparate databases. As a result, there was no effective feedback loop to suppliers, manufacturing production (operational excellence) or product design.

Capturing manufacturing data in one place

What they envisioned was a system that captured all quality information in one place. During production, they wanted to capture detailed test parameters, component and unit test results, in-process repair data, final inspection and field repair data. They wanted to make the data traceable to the component level so they could identify trends and recurring problems, and trace them up and down the supply chain.

They now capture repair data from nearly a dozen processes in a single, central data repository. Once there, the data is accessible to engineers from production, test, and design, as well as operations and quality staff. Users can track defect levels (DPMO) over time, and automatically drill down to get to the root cause of defects.

Driving quality throughout the supply chain

When field failures come in for repair, users can evaluate the problem against all the inputs and processes and drive improvements back to suppliers, product and manufacturing design, and manufacturing processes. They can also look downstream to predict who might have similar problems and take proactive steps to service customers before they have a problem.

The positive impact on the business has been significant. Cheaper, more reliable, and more accessible data enabled the manufacturer to drive defects out of the process, which in turn drives faster throughput, and reduced scrap and inventory carrying costs. Capturing adding field repair data translates the customer experience directly into actionable manufacturing intelligence. That in turn empowers change that improves the customer experience and enables the company to continue to innovate and lead their market.

What is your strategy and focus in the coming years? How do you weight the relative importance of customer experience, operational excellence, and market leadership in your strategy? How does real-time manufacturing intelligence support your drive for supply chain excellence?

Leave a comment, below, or request a free consultation with our staff to discuss your situation, and learn how GainSeeker Suite can empower you to turn manufacturing big data into real-time actionable intelligence.